Performance characteristics

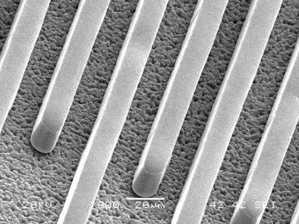

It is suitable for semi-additive process flow, and can complete film stripping of lines with line width spacing of more than 16 ?m/ 16 ?m

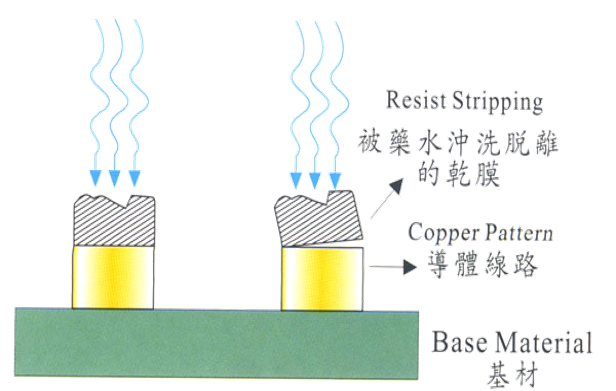

It is also applicable to the removal of secondary dry film after selective nickel gold deposition, and has no attack on gold surface and solder resist layer

The strip time of dry film is short. The strip time of ordinary dry film (such as Asahi Huacheng yq40) can be completed in 30-40 seconds, and that of secondary dry film can be completed in 90-100 seconds

Strong compatibility, without any change to the material of the equipment

The installation of filter will effectively reduce the consumption

Treatment effect

Adhesive: bond other components into a whole

Photoinitiator: during exposure, the photoinitiator in the illuminated area is activated to initiate polymerization of the monomer in this part

Monomer: the unpolymerized monomer is soluble in the developer, while the polymerization is insoluble in the developer

Plasticizer: increase the fluidity of dry film when pasting film

Adhesion promoter: increase the adhesion between dry film and copper foil

Dye: discoloration after exposure to facilitate the inspection of dry film image

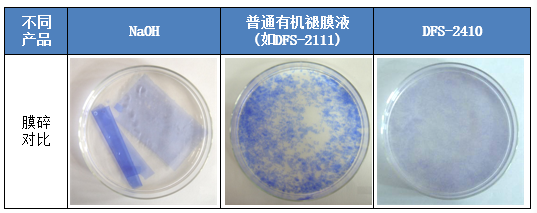

Comparison of film fragmentation of different film removers

Due to the different working mechanism of film removal, the size of dry film fragments removed by organic film removal solution is smaller than that removed by NaOH

SCAN